With over 9 years researching and developing, XST presents an easy solution of manufacturing high quality wheel weights by our fully automatic die casting machine XST-C700 Series.

Our machine can make either zinc (lead free) or traditional lead wheel balancing weights.

XST-C700 Series provide a perfect solution for producers looking to re-equip or update their productivity and manufacturing ability. It is also a good choice for manufacturers looking to start up wheel weight business due to its initial low costs and easy operation.

Technical Data

XST-C700-Z:Zinc clip on weights, size 5gr-120gr

XST-C700-L:Lead clip on weights, size 5gr-120gr

XST-C700-T:Lead truck weights size 50gr-400gr

XST-C700-LA: Lead adhesive weight, forged type

Parameters

| Melting Pot Capacity | 130kg /286lb |

| Electrical | With heating elements 220/380VAC/24V DC, 3 phases. With gas burner: 220V AC/24V DC single phase. |

| Air System | 0.8 MPA, Capacity 0.7CBM. |

| Machine Dimension | 1050x1000x1250mm ( L x W x H) |

| Floor Space | 3.5M2/38ft2 |

| Production Rates | Passenger cars weight Average 500-600pcs/hr; Truck weight Average 120pcs/hr |

| Sprue Heater | 2kw |

| Furnace Elements | 10kw |

Important Features

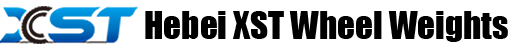

Innovative injection and mold design for quick die changeovers.

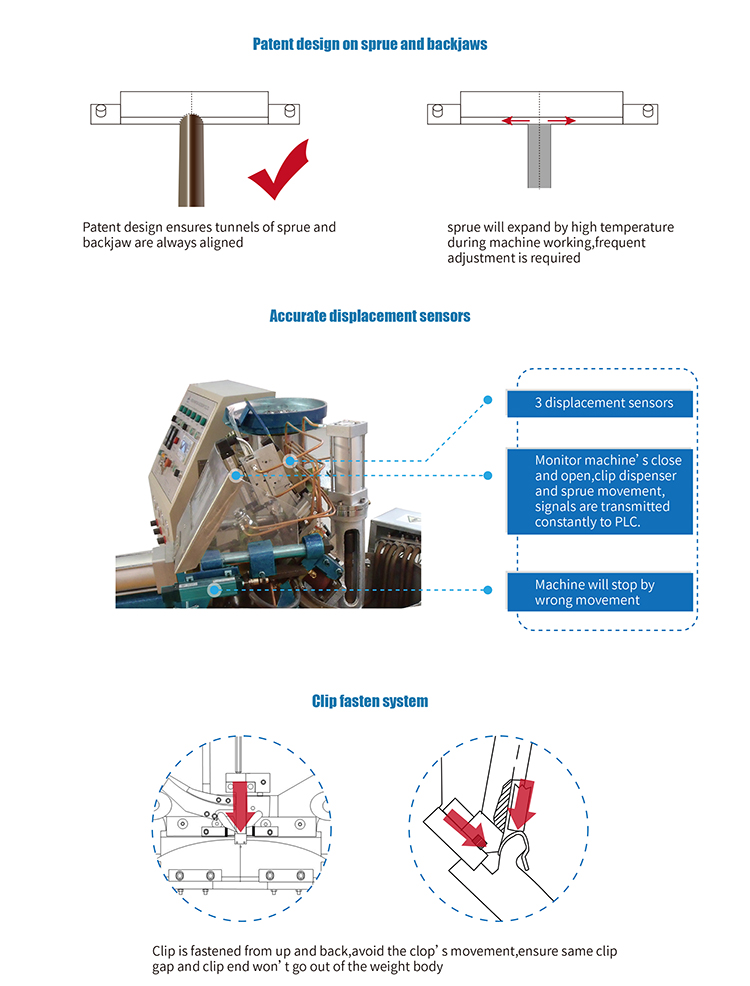

Smart error detective and shut down system avoid material flashing.

Well-designed programme ensure unified clip gap.

Calculation of volume & density from 3D drawing ensure tight mass tolerance.

Certificate

The machine has possessed CE certificate and Certificate of Utility Model Patent

Why choose XST machine?

Our Service

Technical support

Customer training

Spare parts distribution

Repair and service

Mould design & manufacturing

Video

For clip-on weights

* Specifications and machine photos subject to XST’s modification in the case of any improvement.